Foam concentrate solution plays a critical role in modern fire protection systems, especially in combating flammable liquid fires and high-risk industrial hazards. This in-depth article explains what foam concentrate solution is, how it works, the different types available, key applications, standards, environmental considerations, and best practices for storage and maintenance.

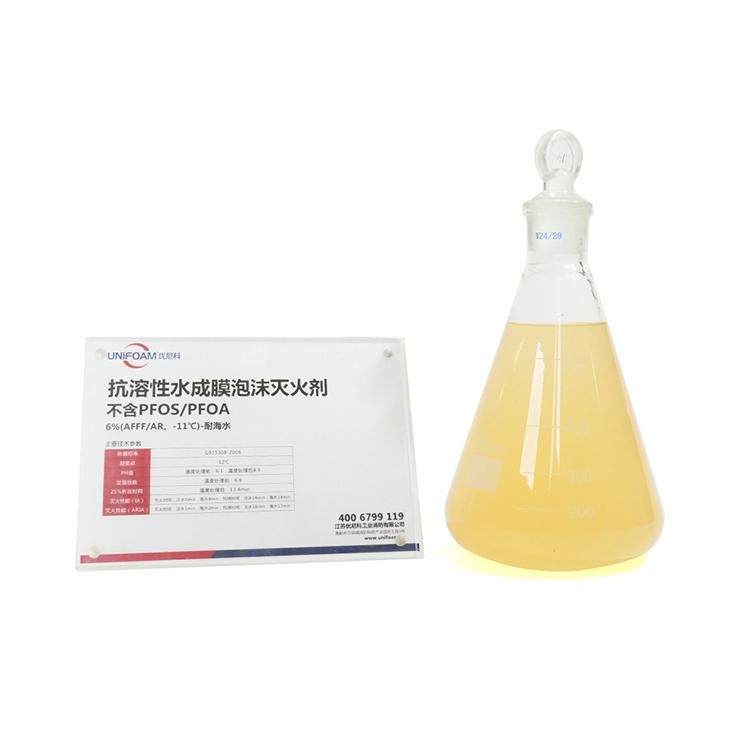

A foam concentrate solution is a specialized fire suppression agent designed to be mixed with water and air to produce firefighting foam. This foam forms a stable blanket over flammable materials, suppressing fire by cooling the fuel, separating oxygen, and preventing the release of flammable vapors.

Unlike plain water, foam concentrate solutions are highly effective against Class B fires involving flammable liquids such as oil, gasoline, solvents, and chemicals. They are widely used in fixed fire protection systems and mobile firefighting equipment.

Foam concentrate solution works through a multi-stage physical and chemical process:

This mechanism makes foam concentrate solution especially effective in large-scale industrial fires where water alone would be insufficient.

| Component | Function |

|---|---|

| Surfactants | Reduce surface tension and improve foam spread |

| Foam Stabilizers | Enhance foam durability and burn-back resistance |

| Solvents | Ensure uniform mixing and storage stability |

| Additives | Improve corrosion resistance and performance |

Each type is engineered for specific fire scenarios, fuel types, and environmental requirements.

Foam concentrate solutions are widely used in:

High-quality foam concentrate solutions should comply with:

Products from Plent are engineered to meet or exceed these global standards, ensuring reliability and compliance.

With growing environmental awareness, many industries are transitioning to fluorine-free foam concentrate solutions. These alternatives minimize environmental impact while maintaining effective fire suppression performance.

Plent actively develops environmentally responsible foam concentrate solutions aligned with evolving regulations and sustainability goals.

As a trusted manufacturer and supplier, Plent delivers high-performance foam concentrate solutions designed for demanding industrial environments. With strict quality control, international certifications, and technical support, Plent helps customers enhance fire safety while meeting regulatory and environmental requirements.

Most foam concentrate solutions are designed for 1%, 3%, or 6% mixing ratios, depending on application and fire risk.

Yes, many formulations are compatible with both freshwater and seawater, especially for marine applications.

When stored correctly, high-quality foam concentrate solutions can have a shelf life of 10–20 years.

Modern fluorine-free foams have achieved comparable performance levels and are increasingly adopted worldwide.

In conclusion, understanding what foam concentrate solution is and how it works is essential for designing effective fire protection systems. Whether you are upgrading existing infrastructure or planning a new facility, choosing the right solution makes all the difference.

For tailored fire suppression solutions, technical consultation, or product selection guidance, contact us today and discover how Plent can support your fire safety strategy.